Cenaero (BE)

Cold Drawing Process

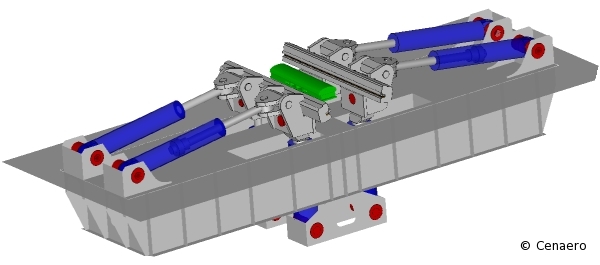

The cold drawing process is often used in aluminium sheet forming. During this process, the sheet is bent and stretched on a forming block. The latter varies for each part and is usually shaped exactly like the target geometry shape. This may lead to significant problems such as the phenomenon of spring-back which most of the time takes place during the unloading of the sheet or during some of the various stages of postprocessing (cuttings, chemical machining...). The amplitude of this phenomenon can be reduced by increasing the drawing and hence plastic deformations. However, deformations are bounded by the material formability. In certain circumstances, excessive spring-back is unavoidable and prevents the use of the block for forming. Formed sheets must then be further processed on other machines, resulting in extra costs and possible problems of part quality. A solution to this problem is to evaluate the spring-back and to account for it by a modification of the block geometry. Another solution is to act on the kinematics parameters to define the optimum deformation rate and speed that will minimise the spring back. An optimization process could be used to determinate which shape of block is to be adopted.

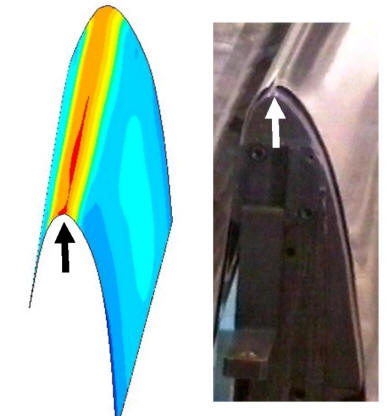

Numerical analysis versus experimental results

Website maintained by the University of Cambridge

Last modified, January 2006