The proposed “Underground M3 system” has two monitoring strategies; (a) Micro-detection and (b) Micro-monitoring and micro-communication. It incorporates innovative diagnostic technologies for asset management that are put into practical and successful use. Therefore, the CRP strategy is a system development that is truly multi-disciplinary with electrical/information experts working closely with civil engineering experts. The details of the collaboration are described in Section A.10. This section gives an overview of the system development. Specific tasks of the development are described in Section B. a) Micro-Detection - Real-Time Damage Detection using Computer Vision

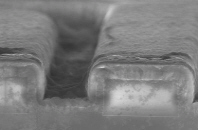

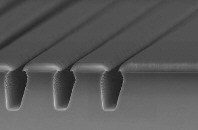

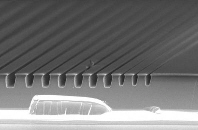

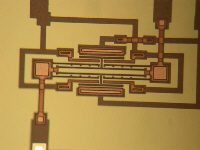

b)Micro-Monitoring – MEMS Strain Sensors

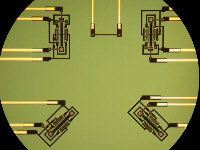

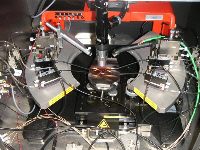

c) Micro-Communication with Power Harvesting - In-Ground Wireless System

To ensure maximum efficiency and network life, the proposed micro-communication systems will operate under low power consumption conditions. In addition, we propose to develop an energy harvesting unit integral with MEMS/Wireless communication technology that will power these devices. This solution is practical as the sensors will be used for long-term monitoring and as a result will not be required to make measurements very frequently. It is proposed to use the energy available in the surrounding environment (e.g. harnessing energy from pressure fluctuations and wind flow while trains are running). d) System Integration, Data Management and Decision making There is limited availability of information regarding new innovative sensors such as MEMS and Wireless technologies to be used in underground environment. Clearly, a technology barrier exists. This is not due to lack of need of new technologies, but perhaps more related to strict regulations adopted by the industry. For example, there are very strict regulations on the embedment of sensors within water pipes or transit tunnels for obvious reasons of human health, safety and security. New technologies have to be assessed for their safety and robustness. We will examine this important issue as part of system integration. The new developed technologies will be tested on individual localities, with different construction systems, with different age of underground structure, different loading given by different depth and geological profiles. Tunnels of Prague Metro will be used as the first field trial sites. The investigation includes (i) detailed analysis of current condition of the tunnels, (ii) comparison of existing monitoring technologies to the newly developed system, and (iii) long-term performance of the new system. The obtained data will be analyzed, e.g. the relation between classical methods of monitoring and the new ones, the possibility to obtain information about small deformation change in time in micro scale, etc. The results will be also compared with numerical methods used for estimation of ageing of underground structures obtained by other partners involved in the project. A guidance report on implementation of the proposed new methods of monitoring and a business plan for commercialisation will be published. In addition to the Prague Metro sites, the new system will be tested in other European sites in collaboration with the associate partners (i.e. London Underground, Madrid Metro and Barcelona Metro). We also plan to expand the application to other potential candidate localities include water and sewage pipes, communication tunnels and underground nuclear waste repositories.

|

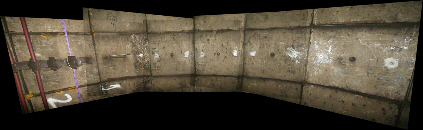

Due to public pressures to run metro systems for 24 hours as well as limited human resources, we expect that the current method of network-wide visual inspection will be difficult to conduct in the future. Instead of network-wide visual inspection of underground infrastructure by means of direct inspection (in person) or remote measures using geometry inspection devices or “pigs”, there is a need to conduct inspection more rapidly and automatically. We propose to develop a real-time damage detection system using new advances in computer vision compared to the existing surface imaging technologies. It is important to note that the currently available technologies are static camera-based, whereas the new system utilises video camera for fast data acquisition during inspection. The proposed system will detect surface cracks and colour changes as a Tier 1 assessment.

Due to public pressures to run metro systems for 24 hours as well as limited human resources, we expect that the current method of network-wide visual inspection will be difficult to conduct in the future. Instead of network-wide visual inspection of underground infrastructure by means of direct inspection (in person) or remote measures using geometry inspection devices or “pigs”, there is a need to conduct inspection more rapidly and automatically. We propose to develop a real-time damage detection system using new advances in computer vision compared to the existing surface imaging technologies. It is important to note that the currently available technologies are static camera-based, whereas the new system utilises video camera for fast data acquisition during inspection. The proposed system will detect surface cracks and colour changes as a Tier 1 assessment.

The data obtained from the micro-monitoringsensors needs to be transmitted effectively to infrastructure owners. This also involves communication to other underground infrastructure owners since it is common that a failure or activity associated with one type of infrastructure impacts on or induces another failure in neighbouring infrastructure. Problems also arise from the complex structure of monitoring and maintenance operations adopted by ageing infrastructure owners. It is often the case that discrete

The data obtained from the micro-monitoringsensors needs to be transmitted effectively to infrastructure owners. This also involves communication to other underground infrastructure owners since it is common that a failure or activity associated with one type of infrastructure impacts on or induces another failure in neighbouring infrastructure. Problems also arise from the complex structure of monitoring and maintenance operations adopted by ageing infrastructure owners. It is often the case that discrete information and technical knowledge of circumstances surrounding pipeline or tunnel failures are scattered within a company. There is therefore a need to develop a common communication protocol (CCP) in which sensors in one type of infrastructure can effectively communicate with sensors in surrounding infrastructure.

information and technical knowledge of circumstances surrounding pipeline or tunnel failures are scattered within a company. There is therefore a need to develop a common communication protocol (CCP) in which sensors in one type of infrastructure can effectively communicate with sensors in surrounding infrastructure.